| General

History indicates that:

- Almost 60% of Rejected Takeoff (RTO) decisions by airline

crews are incorrect, often leading to the aircraft overrunning

the end of the runway.

|

- About 50% of all airliner accidents occur

during the approach/landing phase of the flight.

|

- About 28% of all airliner accidents occurring

on the runway are the result of “overruns”.

|

A factor in many, but not all overruns, is that the runway was

contaminated by water, ice, snow, or slush (wet snow). It is important for

you, as the future operator of airline type aircraft, to know that

anything other than a perfectly dry, sealed runway, may significantly

reduce braking force applied through the tyres.

Hydroplaning

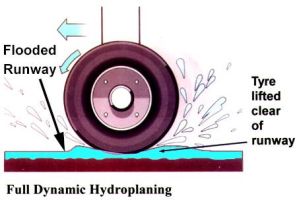

Definition: This describes a situation when a tyre is

lifted clear of the runway due to fluid pressure beneath the tyre. Such a

condition happens mostly when the runway is wet, and occurs when fluid

(water, slush) is not displaced at a rate fast enough from the tyre/ground

contact area (footprint). A melted area of tyre can achieve the same

effect, whether on a wet or dry runway (called “Reverted Rubber

Hydroplaning”).

The result of the tyre not being in touch with the runway

is a total loss of braking ability. When hydroplaning occurs, the tyre

rides or skids on a wedge or film of fluid over all or part of it’s

footprint area. This wedge is the residual surface fluid that has not been

removed by the tyre from the footprint area. As speed increases the wedge

moves further back on the footprint area, until at “Full Hydroplaning

Speed” it has lifted the tyre clear of the runway surface. At lesser

speeds there may be “Partial Dynamic Hydroplaning”.

Water, and contaminated water has extremely low friction

capability, and so a tyre riding on a film of water has little or no

braking friction at all.

|

The build up of fluid pressure beneath

a tyre depends on:

- tyre pressure

- fluid layer thickness

- fluid density and viscosity

- runway texture

- tyre tread pattern and depth

- groundspeed

|

Full dynamic hydroplaning.

Tyre “planes” on standing water.

|

|

Dynamic hydroplaning

Really, this can be split into two sub-types, namely “Partial

Dynamic Hydroplaning”, and “Full Dynamic Hydroplaning”.

Partial dynamic hydroplaning occurs regularly when operating

on contaminated runways, and the antiskid system does a very good

job of limiting it’s effect on braking.

This is where PART of the tyre is lifted off the

runway due to the effect of the fluid

wedge. It can occur to a grooved treaded tyre at water depths of

about 2mm or more. |

|

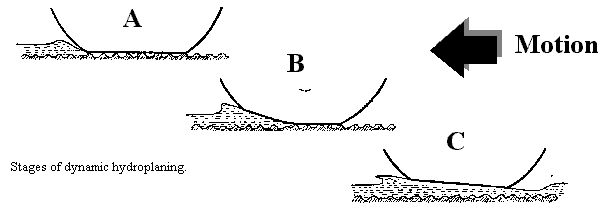

The above diagram shows three wheels

at various groundspeeds on the same flooded runway.

At “A” the aircraft is moving forward slowly, and the

entire footprint is in contact with the pavement. The tyre is

managing to “pump” enough water off the runway as the wall of

water built up at the front is small.

At “B” the aircraft is moving at such a speed that the

wall of water ahead of the tyre cannot be entirely pumped off the

runway surface, and a wedge of water is lifting part of the tyre

clear of the runway. This is partial dynamic

hydroplaning.

At “C” the aircraft has accelerated to it’s full

dynamic hydroplaning speed, as witnessed by the entire tyre

being lifted off the runway. This means, in the case

of the B747-400, the entire 397, 000 kg weight of the aircraft at

takeoff is being supported on a film of water only a few millimetres

thick.

Finding the minimum speed for hydroplaning

The major factor involved in determining the hydroplaning speed

of a tyre is it’s tyre pressure.

There are other factors, which due to their variability are hard

to quantify. They are:

- Tyre wear (ie: tread depth)

- Runway surface texture, and whether the runway surface is

grooved.

- Contaminants on the runway such as rubber deposits and runway

markings.

For theoretical calculation purposes these can be ignored when

finding full hydroplaning speeds.

The Full Hydroplaning speed for a tyre depends on

whether it is rotating, and therefore able to pump water off the

runway surface, or is not rotating (not able to pump water off the

runway).

Remember that tyres may be considered as pumps, and a pump that

is not turning cannot move any fluid.

In effect the speed formula for a non-rotating wheel relates to a

wheel landing on a puddled runway.

The rotating wheel formula is for a tyre rotating during the

takeoff phase, or after the wheel has “spun-up” after landing.

|

Rotating wheel

formula on flooded runway

Minimum FULL Dynamic Hydroplaning speed is 9

x ÖTyre pressure (PSI)

This formula gives the theoretical minimum speed

in knots required to lift the entire tyre up off the

runway. The tyre pressure is in pounds per square inch (PSI).

As an example, the average airliner tyre pressure is about 160

psi. The minimum full dynamic hydroplaning speed of the

tyre is 9 x the square root of 160, which is about 114 kt. If

you lift off at a speed less than this, you are unlikely to

get to the point where the entire patch area is not in contact

with the runway surface, but you may encounter “partial

hydroplaning” at less than 114 knots.

|

|

Formula for

stationary wheel landing on flooded runway

Minimum speed for FULL dynamic hydroplaning

is 7.7 x

Ötyre pressure (PSI)

In the case of a 160 PSI tyre discussed previously, this

would give a full dynamic hydroplaning speed of around

97 knots. Notice that this gives a lower speed than for a rotating

wheel. Swept wing jet aircraft typically land at around 130

knots, so it follows that a landing onto a flooded runway

could cause some anxious moments until the wheels “spin-up”,

and even then the wheels may fully hydroplane down to the

rotating wheel hydroplaning speed of 114 knots.

Below this speed there may be partial hydroplaning, but the

antiskid system will handle any loss of

traction well.

|

|

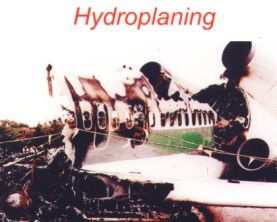

The twin jet aircraft

was being flown by a pilot undergoing assessment for entry into

an airline that operates in the tropics. The aircraft was

approaching to land on a runway that had been very recently

lashed by a severe tropical downpour. A considerable depth of

water was still on the sealed runway as the aircraft landed. The

pilot being tested pulled off a “greaser” landing and was

rather proud of this achievement, thinking he had impressed the

Check Captain. After pulling the aircraft up at the terminal,

the Check Captain told the pilot to never land the aircraft in

such a manner again. The pilot asked, “Why not?”. The Check

Captain explained to him that touching down so gently inhibits

wheel spin up and increases the chances of Full Dynamic

Hydroplaning, and Reverted Rubber Hydroplaning.

|

|

It is extremely

important to land firmly on a flooded runway, so that the tyres

break through the surface water and

“bite” into the runway surface and get the wheel rotating.

This will reduce the chance of hydroplaning and may significantly

reduce the landing distance.

|

|

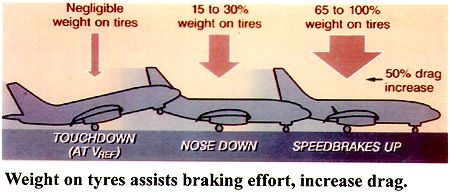

Once the aircraft has

landed, you should lower the nose onto the runway without delay.

This reduces the angle of attack (and lift) and places more of

the aircraft weight on the tyres, which will also reduce the

chances of hydroplaning. |

|

As a guide, Full

Dynamic Hydroplaning is most likey when water depth on runway

exceeds 6mm (1/4 inch). |

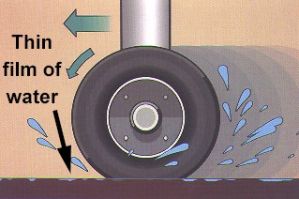

| Viscous Hyroplaning

This usually occurs on very smooth runway surfaces, with as

little as 0.025 mm of water depth.

Major danger areas are on the white runway markings such as

the piano keys, and the 500ft and 1,

000 ft touchdown markings. Also of danger is the

runway touchdown zone, about 1, 000 to 1, 500 ft past the

threshold where most aircraft land. This area becomes

contaminated with burnt-on rubber deposits, which have the

affect of smoothing out the runway

surface by filling in the minute gaps between

the grit.

These areas of rubber build-up are supposed to be cleaned off

by airport operators, but don’t count on it.

Viscous hydroplaning is often associated with contaminated

runway surfaces, not just wet ones. Probably the worst scenario

for creating a viscous hydroplaning event is when contaminants

build up on the runway surface over a long dry spell of weather,

followed by a dew, or very light rain. An aircraft touching down

on a part of the damp runway that is contaminated with rubber

deposits may experience the same degree of traction as it would

if landing on an ice covered runway. Rubber, landing on rubber

with a little bit of water between them make a slippery and

dangerous sandwich combination. There is no set formula for

calculating viscous hydroplaning, but bear in mind it can

persist down to normal taxi speeds.

The runway contaminant could be ice, for which the minimum

speed for hydroplaning is anything faster than a

complete stop. |

Viscous Hyroplaning. |

|

|

Wet snow (slush) is often encountered on

runways in Europe and North America. Slush has a much higher viscosity

than that of water, therefore viscous hydroplaning can occur on slush

covered runways to much lower speeds than for water covered runways. |

|

A runway that is contaminated with rubber

deposits, oil, or mud, in addition to being wet is called a “Slick

Runway”. |

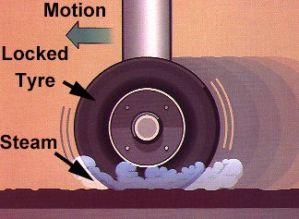

| Reverted rubber hydroplaning

This occurs when a wheel becomes locked up, and can occur on very

slippery or icy runways. It can occur at any speed, and may persist

until the aircraft comes to a stop. It normally follows after either

viscous or dynamic hydroplaning. With the wheel locked up, high

temperatures are formed which result in the tyre rubber REVERTING to

it’s natural latex state. This leads to loss of tyre tread, flat

spots on tyres, and filling of tyre tread with molten rubber. It

also can cause tyre blowouts and tyre fires.

During reverted rubber hydroplaning, the molten rubber forms the

slippery surface for the tyre to ride up on.

On water contaminated runways, the friction of the locked

wheel can cause steam to develop at the tyre footprint. This steam

assists further in lifting the tyre off the runway and melting the

rubber.

There is no speed formula for reverted rubber hydroplaning. |

Reverted rubber hydroplaning. |

End of mini-editorial.

I trust this gives you a new perspective on the dangers of operating on

contaminated runways.

The next mini-editorial will be on the related subject of tyre cornering

ability on contaminated runways.

Goodbye until then !

Rob Avery

Marty says ... "Goodbye to GA".

|

![]()