|

General

Thrust reversal assists greatly in bringing an aircraft to a stop after

landing, or in case of an aborted takeoff. Even more so when the wheel

braking effectiveness is reduced by wet or icy runway surfaces. Reverse

thrust on a dry runway represents about 20% of the total braking force, and

up to 50% on a wet or icy runway. Most jet transport aircraft have reverse

thrust capability, inclusion of which lowers the wear and maintenance levels

of the wheel braking units.

Most turboprop aircraft have a form of reverse thrust also. For now we

will concern ourselves with jet engine reverse thrust.

Principle of operation

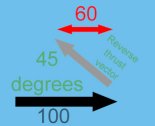

It is important for you to understand that when reverse thrust is

selected by the pilots, the engine does NOT rotate in the opposite direction

to that when developing forward thrust. Furthermore, it does not now suck in

air at the rear of the engine and blow it out the front. The air is

processed in the normal way and deflected forward at an angle of

approximately 45 degrees, by one of four methods which will be discussed

shortly. Because we cannot efficiently turn the air a full 180 degrees, the

maximum amount of deceleration force will be only approximately 50%-60% of

that which can be developed at full forward power (refer fig BGT 1).

| Limitations on use

Reverse thrust is most effective when used at high runway speeds,

and less effective at low speeds, therefore early selection of reverse

thrust is desirable. Use of reverse thrust at speeds below

approximately 60-70 knots can cause engine damage through sand, stones

and other foreign objects entering the intake having been initially

lifted off the runway by the forward flowing air. Surging (compressor

stall) is also a possibility as the hot exhaust air is re-ingested at

the intake.

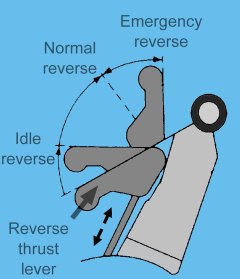

Normally a throttle setting of about 75% N1 speed is used during

reverse operations, 100% N1 in an emergency such as a high speed

rejected takeoff near V1 (refer fig BGT 2).

Reverse thrust can NOT be deployed will in flight, except on a few

aircraft such as the Douglas DC8. |

Fig BGT 1. Reverse thrust vector.

|

| Reverse thrust selection

To select reverse thrust there must first be weight on the wheels. This

is sensed through ‘squat switches’ on the main undercarriage. Secondly,

the thrust lever must be in the ‘idle’ position. Only when these two

pre-requisites are satisfied will an isolation valve open to permit reverse

thrust activation. |

Fig BGT 2. Reverse thrust lever movement.

|

Disadvantages of thrust reversers

Actuation

This is normally achieved using pneumatic bleed air taken from

the engine compressor, though the ‘bucket’ type uses hydraulic

actuation.

Reverse thrust types

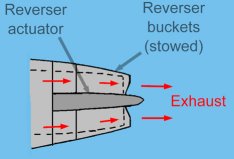

| Bucket

type: This is also known as ‘target type’, and is

hydraulically actuated. In the forward thrust position the thrust

reverser buckets form the convergent/divergent exhaust nozzle of the

engine. In the reverse position the buckets deflect the hot exhaust

gasses forward (refer fig’s BGT 3a and 3b).

|

Fig BGT 3a. Bucket doors in the forward thrust

position.

Fig BGT 3b. Actuator and buckets in the

reverse position. |

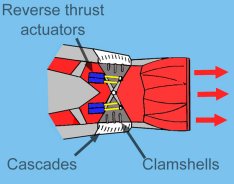

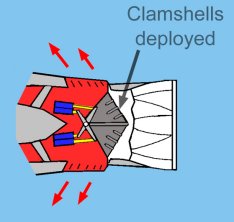

| Clamshell type:

This is a pneumatically operated type using bleed air from that

engines compressor.

The clamshell doors form part of the exhaust tailpipe when in the

forward thrust position. When reverse thrust is selected, the

pneumatic actuators move the clamshell doors so as to block the

escape of exhaust gases, and deflect them forward through forward

angled ‘cascade vanes’. These are only exposed when the

clamshell doors move toward the reverse thrust position. Like the

bucket type, the clamshells operate in the very hot and high

velocity exhaust gas stream, and so must be built of very sturdy

heat resistant metal alloys.

(refer fig BGT 4a and 4b)

|

Fig BGT 4a. Forward thrust position.

Fig BGT 4b. Reverse thrust position.

|

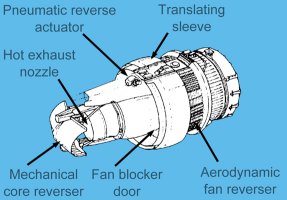

| Fig 5

shows an external view of cascade vanes exposed as translating sleeve

moves rearward.

|

Fig BGT 5. Translating sleeve open.

|

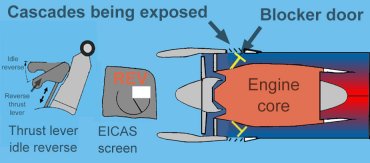

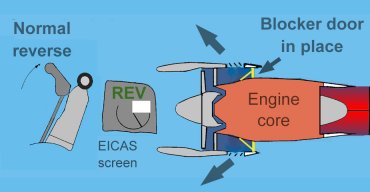

| Fig’s 6a,

6b, and 6c show the progression from forward to

reverse thrust on a General Electric CF6 engine as fitted to a Boeing

B767. Note the EICAS annunciations when blocker doors are in transit, and

when locked in reverse thrust position. |

Fig BGT 6a. Forward thrust position.

Fig BGT 6b. Reverse thrust selected, blocker doors in transit.

Fig BGT 6c. Blocker doors in place.

|

| Bucket/cold stream

combination: This is effectively a hybrid design being both a hot

and cold stream reverser in one (refer fig BGT 7). |

|

Thrust reversal is intended for use

on the runway, though it can be used to reverse the aircraft from the airport

terminal gate. This is NOT recommended practice as it puts ground staff at risk,

can cause engine surging and foreign object damage, and it is difficult for the

crew to steer safely as they cannot see where they are going. If a ground tug is

available for the pushback, use it.

Hopefully this mini editorial on thrust reversers will

help you understand the general principles of interest to pilots. It is an

extract from the training manual called “Basic

Gas Turbines for Pilots”, which will be of interest to those

planning to fly jets, or studying towards there ATPL examination. You can

purchase this book from the ONLINE SHOP

within this website, or at one of the many approved distributors

around Australia.

Avfacts ATPL

training course information is also available in this site, as

are some practice examination

questions on various ATPL subjects.

Finally, good luck with your studies, and remember ...

"Pilots are

always learning"

Best Wishes

Rob Avery

Marty says ... "Goodbye to GA".

|

![]()