| General

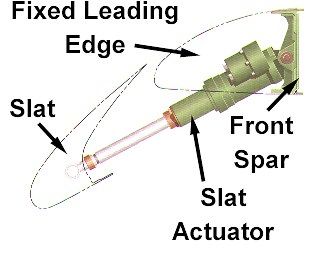

High lift devices for takeoff and landing are provided each wing by 5

outboard and 1 inboard slat section, plus slotted Fowler trailing edge

flaps. Additionally, the inboard ailerons droop with the trailing edge

flaps.

Flap positions are UP, 1, 5, 15, 20, 25, 30. The 25 and 30 are landing

flap selections.

Normal Operation

Under normal operations, the flaps and slats are operated by a single

flap selector lever to the right of the thrust levers. Moving the flap

lever to one of the flap detent's sends signals to 3 Power Drive Unit (PDUís),

which in turn move the flaps and slats.

One PDU drives the inboard leading edge slats. Another drives the 5

outboard slat sections. A third drives the trailing edge flaps. Power to

all is supplied from the centre hydraulic system

.

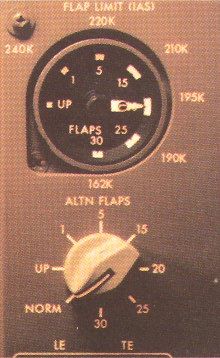

| Flap/Slat position

indicators

A cockpit dial with two pointers (left and right) shows the

actual flap position. If left and right flaps/slats are moving

correctly and in unison, the left point obscures the right point

beneath it. The dial is used to identify the flap/slat position,

during takeoff, approach and landing checks, along with the flap

handle position itself.

- In the UP position, both the leading edge

slats and trailing edge flaps are retracted.

|

- In position 1, the leading edge flaps are

extended to the takeoff position. Trailing edge flaps

remain retracted.

|

- Moving the flap lever to the 5, 15, 20

detent's, drives the trailing edge flaps accordingly. The

leading edges stay in the takeoff position.

|

- Moving the flap lever to the 25 or 30

(landing flap) positions simultaneously moves the leading

edge slats and the trailing edge flaps to the landing

position.

|

| Non-Normal operation

Alternate slat/flap movement is provided by electric

motors, one connected to each of the PDUís. Normal hydraulic

power is by-passed. Pressing either or both the leading edge

or trailing edge alternate flap switches allows the pilot to

select flap using the alternate flap selector knob, which is

next to the flap position indicator dial.

Flap movement is much slower using the alternate (electric

drive) system. It takes about 3 minutes to drive the flaps

from the UP position to the 20 degree position.

Flap asymmetry and flap load relief protection are NOT

provided when using the alternate system. The NORM position on

the alternate flap selector switch is when normal hydraulic

system operation is occuring.

Flap load relief system

Once the landing flap setting of 25 degrees has been

selected, any over-speeding of the flap upper limit speed

causes the trailing edge flaps to retract automatically to the

20 degree setting, thereby protecting the flaps from becoming

over-stressed by air loads.The flap position indicator will

show the change, but the flap lever position will NOT change,

remaining in itís original position. Once the speed has

reduced to below 25 flap limiting speed, the flaps

automatically extend to the lever commanded position. |

|

|

Flap/slat asymmetry protection

Should the leading edge slats, or trailing edge flaps on one wing move

at a different rate to that of the corresponding unit on the other wing,

the flaps/slats will cease to move any more under the normal hydraulic

system. You could use the alternate system but it is not recommended, as

there is no asymmetry protection afforded by the alternate system.

Asymmetric flap/slat is a serious threat, as this can cause uncorrectable

roll due to the different lift being developed by each wing. You may have

to land with whatever flap was lowered when asymmetric flap first was

sensed.

Leading edge or trailing edge disagreement

If either the flaps or slats are NOT driving toward their commanded

position, a warning light illuminates, and an EICAS message appears. Slats

and flaps can be moved using the alternate system.

I hope this mini-editorial assists you in the ATPL Aerodynamics and

Aircraft systems examination.

The next editorial will look at hydroplaning, which is part of the same

examination.

Until then, happy flying !

Rob Avery

ATPL Lecturer

Marty says ... "Goodbye to GA".

|

![]()